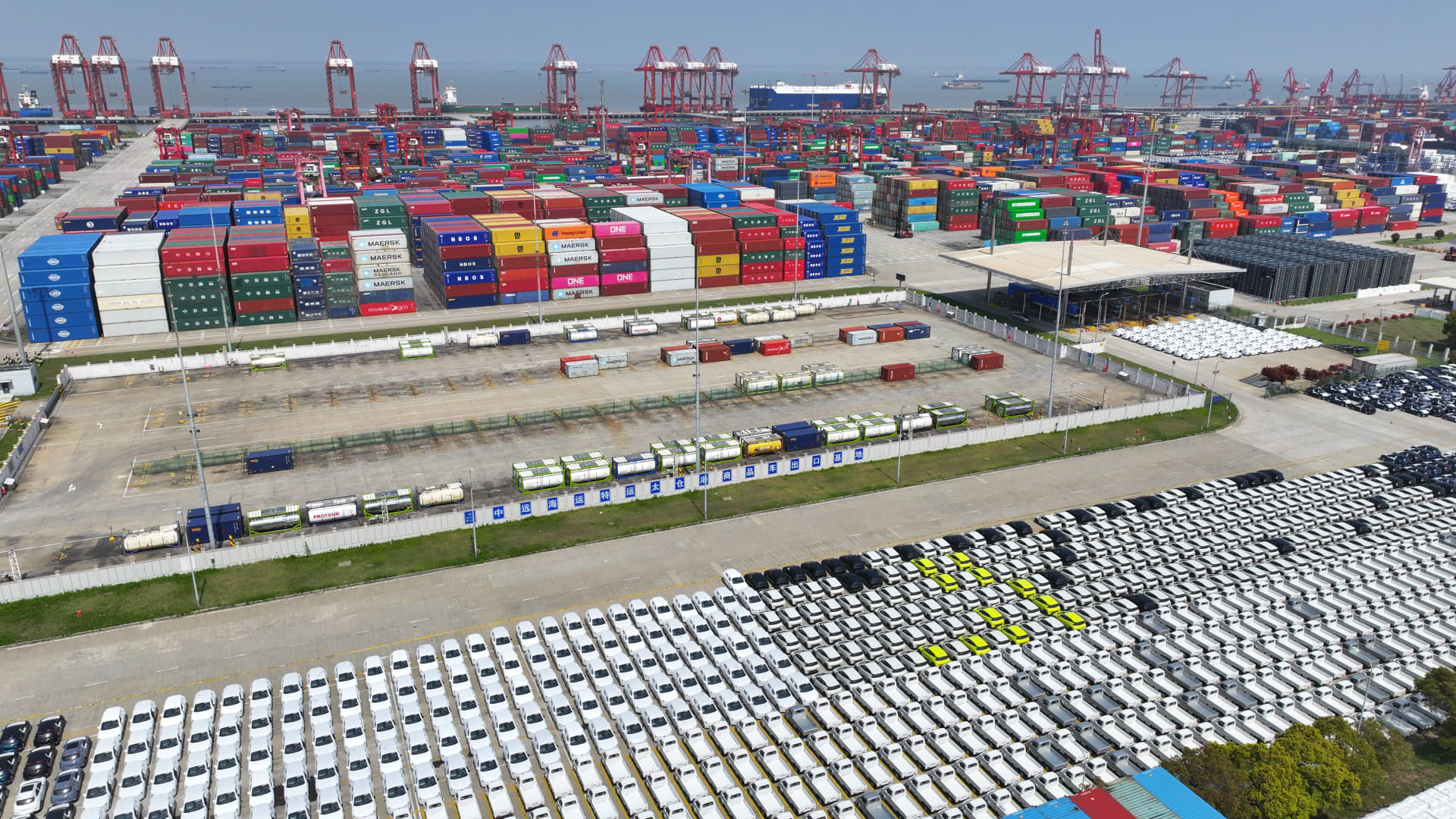

A batch of cars are ready to be shipped to overseas markets at the port of Taicang, Jiangsu province, China, April 9, 2024.

Future Publishing | Future Publishing | Getty Images

Inflation is on the rise again, but it isn’t the only economic indicator rebounding. Imports coming to the U.S. from China are experiencing a notable increase, according to new trade and logistics data.

The rise in import containers originating from China to the U.S. started after the reopening of manufacturing plants that closed during the Lunar New Year celebrations. According to the Global Port Tracker report released by the National Retail Federation and Hackett Associates, inbound cargo volume at the nation’s major container ports is expected to top two million units by May for the first time since last fall, as imports grow despite new supply chain challenges.

The first half of 2024 is expected to total 11.7 million TEUs (twenty-foot equivalent units), an increase of 11% from the same period last year. In 2023, imports were down from 2022 by almost 13%, totaling 22.3 million TEUs.

The trade data is a forward-looking indicator of a strong consumer-based economy, based on freight transit orders placed by U.S. retailers and manufacturers.

U.S. imports are continuing to increase despite multiple supply chain disruptions impacting U.S. ports, noted John Gold, NRF vice president for supply chain and customs policy. Retailers have adjusted to limits on the use of the Panama Canal resulting from drought conditions, the Red Sea attack trade diversions, and most recently, the shutdown of the Port of Baltimore to vessel traffic, which could remain closed for at least weeks more.

“While it is not expected to have a national impact, the tragic collapse of the Francis Scott Key Bridge shows the ongoing need for flexibility and resiliency in every company’s supply chain. We are monitoring the situation closely as retailers who are affected adjust their shipping plans to ensure cargo is getting to where it needs to be,” Gold said.

While an important trade hub, especially for automobile, truck and farm equipment, the Port of Baltimore is not among the largest container ports on the East Coast, processing 1.1 million TEUs in calendar year 2023. By comparison, New York/New Jersey processed 7.81 million TEUs, Georgia 5.4 million TEUs, Virginia at 3.3 million TEUs, Charleston 2.5 million TEUs, Jacksonville 1.3 million TEUs, and Miami 1.25 million TEUs.

Nevertheless, the port diversions and overall rebound in consumer imports is having an impact on supply chain prices, which can be seen in action at the Port of Virginia (Norfolk), where the overall container volume is rising and it is handling Baltimore containers.

Data released on Wednesday by the container trucking directory site Drayage.com shows an uptick in drayage prices in Norfolk based on the demand for this type of truck that moves the containers.

“Norfolk is near pandemic levels,” said Jason Hilsenbeck, president of Drayage.com and LoadMatch. “With the sudden increase in container cargo, Norfolk draymen are charging a premium on dray rates.”

Paul Brashier, vice president of drayage and intermodal for ITS Logistics, tells CNBC that into April and May, new ports (primarily NY/NJ & Norfolk) will become the North American entry point for Baltimore freight. It is tracking spikes in demand for services in Norfolk and New York/New Jersey as more shippers look for assistance in moving their containers because of the Baltimore accident.

“This will increase congestion and challenge operations at these locations, and this unplanned increase in demand will drive dray trucking rates upward. Long-term effects could be further migration of transpacific freight to West Coast North American ports from the U.S. East Coast,” he said.

For rail-bound containers, ITS Logistics’ US Port/ Railroad Freight Index is raising its warning in both drayage operations on the West Coast and rail ramps to “elevated” due to the increase in eastbound freight coming into the Ports of Los Angeles and Long Beach. The combination of the increase in containers versus the amount of rail chassis available to move the containers is off balance, creating a lag in the movement of containers.

Brashier said 25% of ITS client freight is coming back to the ports of Los Angeles and Long Beach.

“Year over year, March and April have been good, up 35% in national import volumes,” he said.

Both directors of the ports of Los Angeles and Long Beach recently told CNBC the increase in eastbound containers heading to their ports is a result of Panama Canal drought restrictions. The other reason for the recent container push is fears of a labor strike at East Coast and Gulf ports. The International Longshoremen’s Association six-year contract with the United States Maritime Alliance, which represents port terminal operators and ocean carriers on the East Coast, expires September 30.

“Due to the ongoing resilience of the American consumer, 2024 imports have maintained their upward momentum,” said Alan Baer, CEO of OL USA. “We expect this trend to continue, however the size of the year-over-year increase may be challenged by stubborn inflation, coupled with higher-for-longer interest rates. The strong U.S. dollar is helping support increased purchasing power for all importers, sheltering to a degree the higher cost of capital.”

Recent Federal Reserve minutes show concerns among central bank officials about inflation not moving down quickly enough, though they still expect to cut interest rates this year.

While the largest contributor to the latest inflation bump was on the services side of the equation, including auto insurance and shelter prices, several goods categories did rise more than expected, including women’s apparel and jewelry. Goods disinflation since the pandemic boom has helped the Fed with its goal of lowering prices, but now the ability of goods prices to contribute to disinflation is becoming more limited, Sarah House, senior economist at Wells Fargo Economics, told CNBC on Wednesday.

According to S&P Global Market Intelligence, U.S. seaborne imports in March were strong, with containerized freight shipments having increased by 16% year over year. This expansion followed two rapid months of growth in January and February, which brought the total for the first quarter of 2024 to growth of 15%, according to Chris Rogers, S&P Global’s head of supply chain research.

“Some caution is needed, however, as the rate of growth is based on a prior year when firms across a range of sectors were rapidly reducing inventories,” Rogers wrote in an email.

On a compound annual basis, shipments have expanded by 3.5% over the past five years. On a year-over-year basis, the S&P data shows that the fastest rates of growth were seen in the materials sector, with an increase of 20%, and paper and forestry products, which saw an increase of 25%. Chemicals and metals rose by 15% and 17%, respectively.